Why do cooling fans need to have the function of resisting environmental erosion (Part 2)

Feng Zhi Yuan

Feng Zhi Yuan

Nov 03,2025

Nov 03,2025

The core reason why a cooling fan must resist environmental erosion is the corrosive factors such as water vapor, dust, and chemical media in the environment, which can directly damage the structure and operational performance of the fan, thereby affecting the cooling efficiency and operational safety of its adapted equipment, and even causing chain failures. The specific reasons can be explained in detail from the following aspects:

3. Avoiding chain reactions of malfunctions and protecting overall equipment safety

Cooling fans are often used as supporting components for core equipment such as industrial equipment, electronic devices, and communication base stations. Their failure may cause serious problems with the overall equipment. On the one hand, fan failure can lead to heat accumulation inside the device, which may burn out expensive core components such as server chips, industrial controllers, etc., causing economic losses far exceeding the value of the fan itself; On the other hand, erosion may also pose safety hazards, such as insulation damage to motor windings caused by water vapor erosion, which can easily lead to short circuits and even cause accidents such as leakage and fire. Especially in special scenarios such as chemical and dusty environments, such risks will be further amplified.

4. Maintain operational stability and adapt to complex application scenarios

The application scenarios of cooling fans are very wide, from damp aquatic workshops, salt spray prone seaside base stations, to chemical plants filled with acidic and alkaline gases, and dusty metallurgical plants. Most scenarios have corrosive factors. If the fan does not have erosion resistance, it will frequently malfunction in these scenarios and cannot meet the requirement of 24-hour continuous operation of the equipment. For example, if the cooling fan of coastal wind power equipment cannot resist salt spray erosion, it will cause interruption of wind power inverter cooling and affect power output; If the laboratory specific fan is not resistant to chemical reagent corrosion, it may suddenly malfunction during the experiment and interfere with the experimental process.

The core significance of the cooling fan's ability to resist environmental erosion lies in ensuring the reliable operation of the equipment throughout its entire lifecycle. From the four dimensions of performance, cost, safety, and compliance, it avoids irreversible damage caused by environmental factors to the equipment, ultimately achieving the maximization of equipment value.

Home

Home

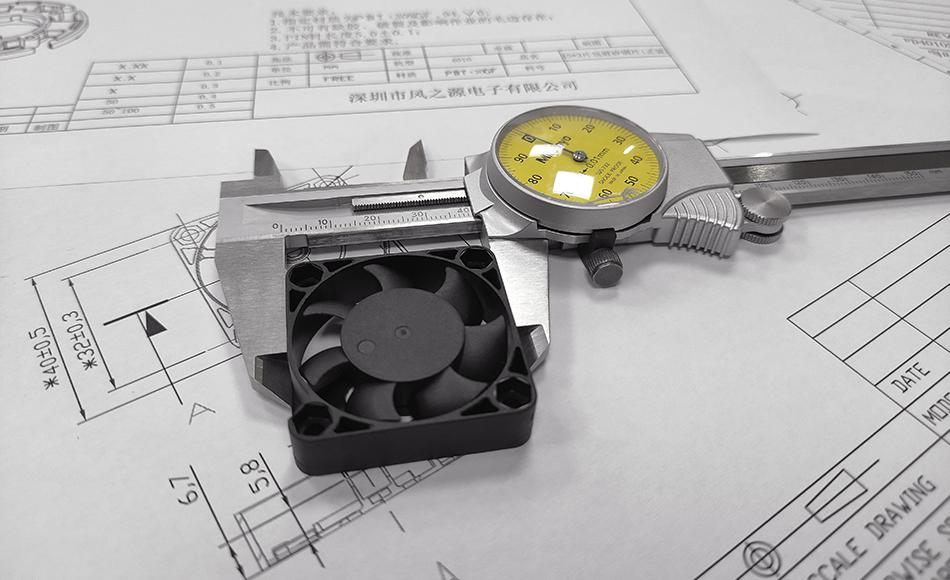

A reliable cooling fan requires material selection and protective design to resist environmental erosion

A reliable cooling fan requires material selection and protective design to resist environmental erosion