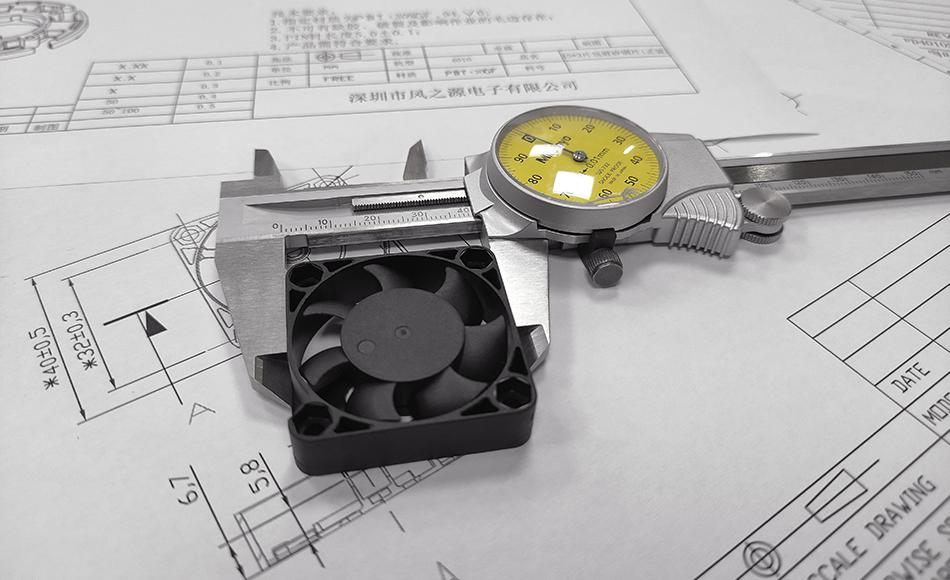

A reliable cooling fan requires material selection and protective design to resist environmental erosion

Feng Zhi Yuan

Feng Zhi Yuan

Nov 05,2025

Nov 05,2025

If the cooling fan is to effectively resist environmental erosion, the reasonable selection of materials is the key foundation, and protective design is an important physical barrier, both of which need to be precisely adapted to the application scenario.

1. Material selection

Corrosion resistant metal materials: Key structural components such as the frame and blades of the fan should prioritize the use of metal materials with strong corrosion resistance. Stainless steel, which contains elements such as chromium, can form a dense oxide film on its surface, effectively isolating oxygen, moisture, and other corrosive substances from contact with the metal substrate, thereby resisting the corrosion of common acidic, alkaline, and salt chemicals. It can also maintain structural stability in humid and chemically polluted environments.

High performance plastic materials: Some special engineering plastics, such as polyphenylene sulfide (PPS), polyetheretherketone (PEEK), etc., have excellent chemical corrosion resistance, high temperature resistance, and mechanical properties. These plastics can be used to manufacture components such as fan blades and casings for fans. They are not only lightweight, but also capable of long-term use in harsh environmental conditions without deformation, aging, or corrosion.

2. Protective design

Protection level design: Based on the usage environment of the fan, design an appropriate protection level (IP level). The IP rating consists of two digits, with the first digit representing the dustproof rating and the second digit representing the waterproof rating. For example, fans with IP54 protection level can prevent dust from entering the interior of the fan and withstand splashing water from all directions, making them suitable for general industrial environments; Fans with IP65 or higher protection levels can completely block dust and withstand low-pressure water flow, making them suitable for more harsh outdoor or humid environments.

Dustproof net design: Installing dust-proof nets at the air inlet and outlet of the fan can effectively block dust, debris, and other objects from entering the interior of the fan. The aperture size of the dust screen should be selected according to the particle size in the usage environment, ensuring good ventilation and effective dust filtration. At the same time, the dust screen should be easy to disassemble and clean for regular maintenance and cleaning, to prevent dust accumulation from affecting the performance of the fan.

Home

Home

A reliable cooling fan requires sealing treatment to resist environmental erosion - intelligent control and monitoring

A reliable cooling fan requires sealing treatment to resist environmental erosion - intelligent control and monitoring