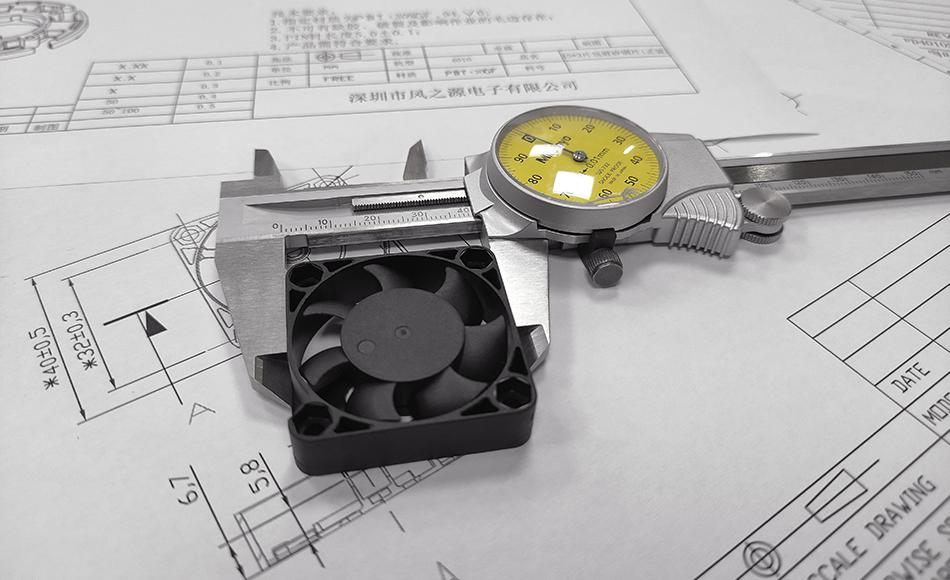

The lifespan of a fan is influenced by multiple factors, including the operational status of key factors

Feng Zhi Yuan

Feng Zhi Yuan

Nov 28,2025

Nov 28,2025

Operation status: determines the "workload" of the fan. The lifespan of a fan depends not only on the quality foundation of the product itself, but also on the "postnatal influence" of operating conditions - it is like the "working intensity dashboard" of the fan, directly determining the rate of internal component wear and tear, which is a key core factor affecting the lifespan.

1、 Speed and load: Overload operation=life "accelerated depreciation"

Each fan has a designed rated speed and upper limit of air volume, which are the "safety thresholds" to ensure long-term stable operation. If in order to pursue short-term stronger heat dissipation effect, forcing the fan to operate at over rated speed (especially over 10%) through voltage regulators and frequency converters may seem to improve heat dissipation efficiency, but it is actually overdrawing the lifespan of the fan:

During high-speed operation, the motor current will significantly increase, resulting in additional current heating losses (copper losses) and causing the motor temperature to soar; At the same time, the centrifugal force of the fan blades doubles, and the radial load borne by the bearings increases sharply, resulting in a geometrically accelerated wear rate.

2、 Start stop frequency: frequent start stop=frequent impact on the fan

The explosive force at the moment of fan start-up causes much more damage to internal components than during stable operation

When starting, the motor needs to overcome the inertia of the fan blades, and the starting current can reach 5-8 times the rated current. This strong current will cause severe "electrical stress impact" on the motor winding (enameled wire), accelerating the aging and brittleness of the insulation layer; At the same time, each start stop will cause the bearing to undergo a frictional switching from "static to high-speed rotation", resulting in uneven distribution of lubricating grease and continued local wear.

If the fan starts and stops more than 10 times per hour (such as in scenarios where equipment operation status is frequently switched), its overall lifespan will be shortened by 30% -50% compared to a fan that operates continuously and stably, and the probability of motor failure and bearing damage will significantly increase.

3、 Running time: Accumulated running=Loss "continuous superposition"

The core indicator of the lifespan of a fan is "accumulated operating hours", which is a direct reflection of component wear - just like the mileage of a car, every hour of operation will cause vulnerable parts such as bearings and motor windings to continue aging:

The rated lifespan of industrial fans is usually between 20000 and 50000 hours, while household fans can reach up to 50000 to 80000 hours; For scenarios such as data centers and industrial production lines that operate continuously 24 hours a day, the wear and tear of fan components will continue to accumulate, and vulnerable parts will age at a fixed rate, inevitably leading to failures when they reach their maximum lifespan.

Long term continuous operation is not "unfeasible", but it needs to be accompanied by regular maintenance (such as lubrication and cleaning) to delay the accumulation of losses and bring the lifespan close to the design limit; If there is a lack of maintenance, even if the operating time does not reach the rated value, it may fail prematurely.

Home

Home

Professional grade cooling fan bearings: key performance support for overclocking and high load scenarios

Professional grade cooling fan bearings: key performance support for overclocking and high load scenarios