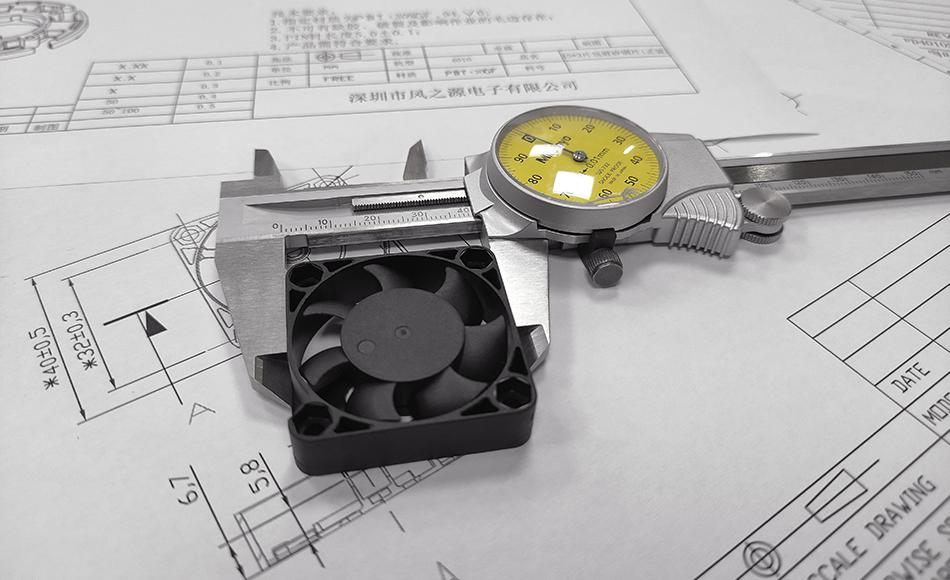

Professional grade cooling fan bearings: key performance support for overclocking and high load scenarios

Feng Zhi Yuan

Feng Zhi Yuan

Dec 05,2025

Dec 05,2025

The cooling fan bearing is the core component that determines the noise, lifespan, and stability of the fan. Its core function is to support the rotation of the fan rotor, reduce frictional resistance, and ensure the long-term efficient operation of the fan. Different types of bearings have significant differences in structure, performance, and applicable scenarios. The following will be discussed from three dimensions: basic concepts, comparison of mainstream types, and selection.

1、 The core function of cooling fan bearings

The core of a cooling fan is "the motor drives the rotor to rotate the fan blades", and the bearings are located between the "stator (fixed part)" and the "rotor (rotating part)", with the main functions including:

Positioning rotor: Ensure that the rotor is concentric with the stator to avoid vibration and noise caused by blade eccentricity;

Reduce friction: Replace metal direct contact with bearing structure to convert sliding friction into rolling friction (or low resistance sliding friction), reducing energy loss;

Load bearing: bear the weight of the rotor and fan blades, as well as the radial/axial pressure during rotation, to ensure long-term operation without displacement.

2、 Comparison of mainstream cooling fan bearing types

At present, the cooling fan bearings on the market are mainly divided into 5 categories, and their performance differences directly affect the user experience (such as noise) and life cycle of the fan. The specific comparison is as follows:

Oil containing bearings: extremely low cost, simple structure, good initial quietness

Hydraulic bearings: have a lifespan 2-3 times longer than oil containing bearings, stable quietness, and moderate cost

Double ball bearings: long service life, high and low temperature resistance (-20 ℃~70 ℃), anti vibration; Friction resistance is stable, and there is no significant increase in noise in the later stage

Magnetic levitation bearings: zero friction, extremely long lifespan (theoretically without mechanical losses), top-level quietness; impact resistance

Ceramic bearings: high hardness (5 times higher than steel), high and low temperature resistance (-50 ℃~150 ℃), corrosion resistance; Low friction coefficient and long lifespan

3、 How to choose bearings based on demand?

1. Prioritize 'usage scenarios':

Daily household use (such as computer cases, CPU heat sinks): choose hydraulic bearings (balanced, silent, and long-lasting);

Long term non shutdown (such as servers, NAS): Choose double ball bearings (resistant to long-term loads, maintenance free);

Ultimate quietness requirements (such as bedroom computers, audio-visual equipment): Choose magnetic levitation bearings (no physical friction, noise<15dB);

2. Secondary consideration of "environmental conditions":

High temperature environment (such as near the CPU in the chassis, industrial equipment): Avoid oil/hydraulic bearings and choose double ball bearings or ceramic bearings;

Wet/corrosive environment: Choose ceramic bearings (corrosion-resistant) or sealed double ball bearings.

Home

Home

Dynamic balancing technology: Say goodbye to vibration and noise in the cooling fan, and radiate long-lasting power

Dynamic balancing technology: Say goodbye to vibration and noise in the cooling fan, and radiate long-lasting power