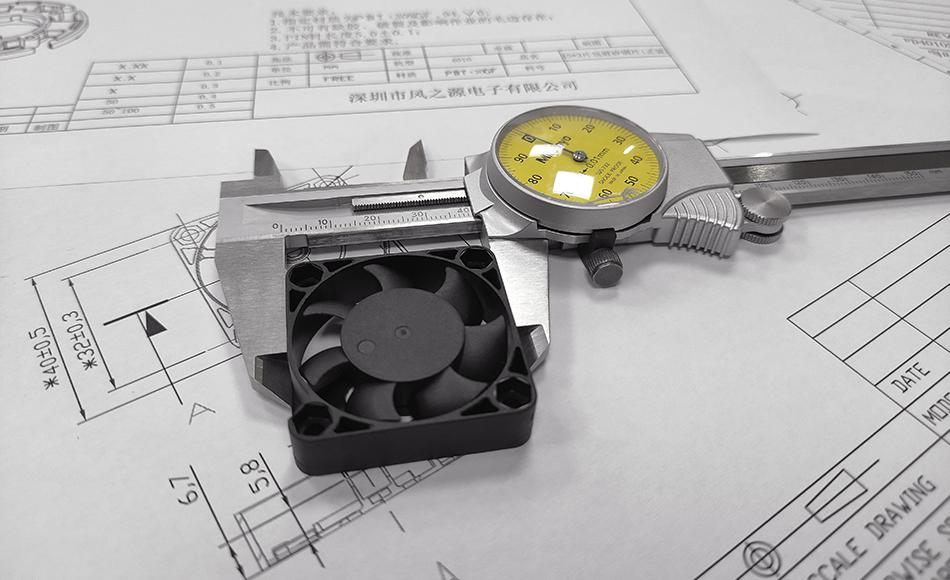

Metal cooling fan--- responsible for stability under high temperature and high load conditions

Feng Zhi Yuan

Feng Zhi Yuan

Dec 29,2025

Dec 29,2025

Metal cooling fans (mainly made of aluminum alloy, steel, magnesium alloy) have high strength and other characteristics, but also have limitations in weight and other aspects.

1、 Core advantages

High temperature and deformation resistance, suitable for harsh working conditions

Metal cooling fans can withstand temperatures above 150 ℃ for a long time and will not experience softening or other issues in high-temperature environments like plastic fans. At high speeds, the deformation of the blades is small, which can maintain the accuracy of the airfoil and ensure stable output of air volume and pressure.

High structural strength, good impact and vibration resistance performance

Metal materials have better impact and vibration resistance than plastics, making them suitable for industrial scenarios with high dust and strong vibrations. A small amount of dust adhering to the blades is also less likely to cause resonance due to center of gravity deviation, which can extend the service life of the bearing.

Assist in heat conduction and improve heat dissipation efficiency

Metal has good thermal conductivity, and when the blades rotate, they can take away some of the equipment's heat. In a closed high-temperature chamber, it can compensate for insufficient airflow heat dissipation, and the overall heat dissipation efficiency is 10% -15% higher than that of plastic fans of the same specification.

Strong durability and long lifespan

Metal cooling fans have no risk of aging or brittleness, and under standard maintenance, their design lifespan can reach 80000 to 120000 hours, far exceeding that of plastic fans. They are suitable for 7 × 24-hour uninterrupted operation equipment.

2、 Areas to be optimized

Heavy weight and high startup power consumption: Metal blades have high inertia and require higher current during startup, resulting in slightly higher energy consumption than plastic fans of the same specifications.

Relatively high noise: Metal materials have strong vibration conductivity, and the vibration of the blades is easily transmitted to the frame during high-speed operation, generating high-frequency noise; And the acoustic characteristics of metal blades rubbing against air are more "sharp".

High cost and complex processing: It needs to be formed through stamping, die-casting, and CNC machining, and cannot be mass-produced like plastic. The unit price is 2-5 times that of plastic fans.

Home

Home

What is a high air volume fan?

What is a high air volume fan?