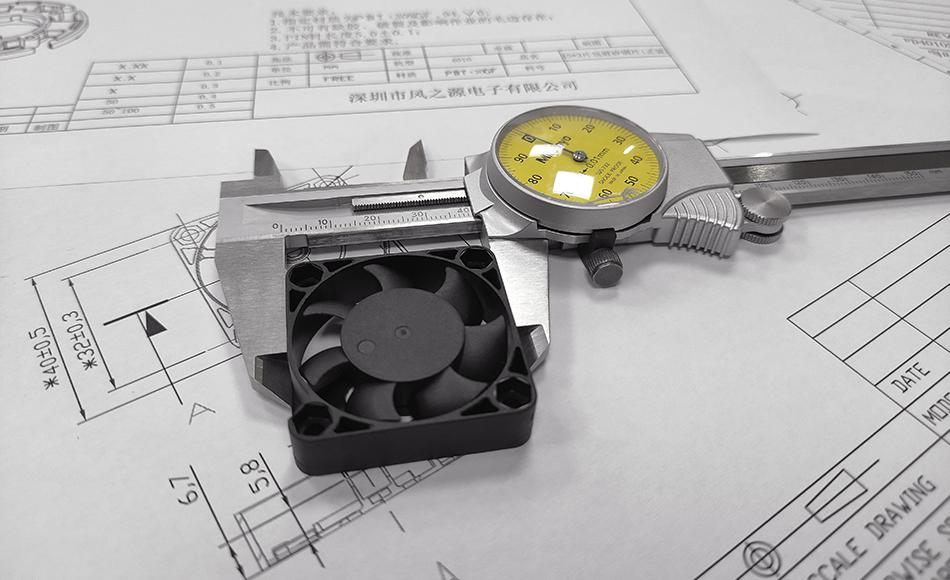

The exhaust effect of the external air outlet of the cooling fan --- fan performance

Feng Zhi Yuan

Feng Zhi Yuan

Oct 10,2025

Oct 10,2025

1、 Core performance parameters of the fan itself (determining the "source power" of the airflow)

The fan is the "power source" for the exhaust effect, and its own performance directly determines the initial intensity of the airflow. Key parameters include:

1. Airflow and Air Pressure

Airflow: The volume of air that a fan can push per unit of time (commonly measured in CFM - cubic feet per minute) m³/h), It is the basis of "exhaust volume size". The larger the air volume, the more hot air is theoretically discharged per unit time.

Wind pressure: The ability of a fan to overcome airflow resistance (commonly measured in mmH ₂ O, Pa) is the key to whether it can send out wind. If the path of the air outlet is curved, narrow, or obstructed by grilles, insufficient air pressure can cause the airflow to be "blocked in the middle", and even if the air volume is high, the exhaust effect will sharply decrease.

Core relationship: The air volume and air pressure are in a "reverse balance" - for fans of the same size, pursuing high air volume often requires sacrificing some air pressure (suitable for open, low resistance exhaust scenarios); To pursue high wind pressure, it is necessary to reduce the air volume (suitable for complex and high resistance scenarios such as laptops and dense heat sinks).

2. Fan efficiency and speed

Speed: In theory, the higher the speed, the faster the frequency at which the fan blades cut the air, and the air volume and pressure will increase synchronously (under the same fan model). But the higher the speed, the better:

Excessive rotational speed can lead to a surge in noise and an increase in motor heating (which in turn consumes some of the heat dissipation capacity);

If the fan operates at low efficiency and high speed (such as high motor losses or unreasonable fan blade design), the actual increase in exhaust air is much lower than the increase in speed.

Motor efficiency: The efficiency of brushless motors (conversion rate of electrical energy to mechanical energy) directly affects the "effective power" - high-efficiency motors can convert more electrical energy into the rotational kinetic energy of the fan blades, reduce ineffective heating, and avoid speed decay caused by motor overheating.

3. Fan blade design (determining the "propulsion efficiency" of airflow)

Fan blades are the direct drivers of airflow, and their structural design affects the "continuity" and "resistance adaptability" of airflow:

Number of fan blades: few fan blades (3-5 pieces). Fans usually have fast wind speed and high air volume, but low air pressure (suitable for low impedance scenarios); Multi blade (7-9 blades) fans have smoother airflow and higher wind pressure (suitable for high resistance scenarios).

Fan blade angle and curvature:

Excessive angle of attack (angle with the rotating plane) of the fan blades can lead to increased turbulence in the airflow (high wind resistance, high noise); If it is too small, the efficiency of pushing air will be low (insufficient air volume).

Curved/streamlined fan blades can reduce the separation of airflow on the blade surface, lower vortex losses, and allow airflow to enter the air outlet more smoothly.

Edge treatment of fan blades: Fan blades with "serrated edges" or "guide grooves" can reduce airflow disturbance during blade rotation (especially at high speeds) and improve exhaust stability.

Home

Home

Exhaust effect of external air outlet of cooling fan - duct design

Exhaust effect of external air outlet of cooling fan - duct design