Get to know uS

-

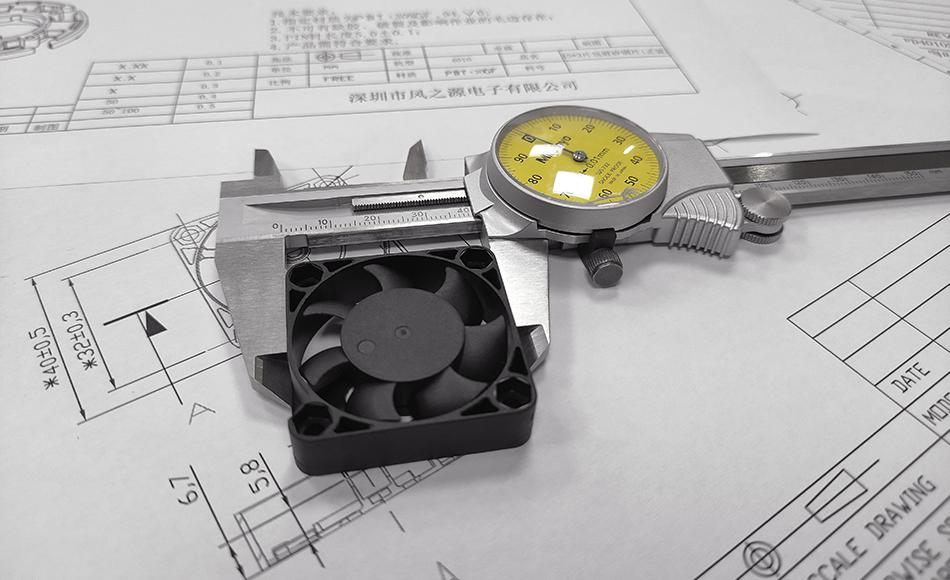

Company Profile

We are a comprehensive service provider that integrates R&D, production of DC Fans, and provision of cooling solutions. -

Development History

FZY's output value grows at a rate of over 30% annually -

Company Advantages

Integrated services of R&D, production, testing and maintenance led by intelligent equipment -

Company Certification

FZY has passed ISO9001/IATF16949/ISO14001 management system certification -

News

Understand the latest news of the company and industry

Heat Dissipation Case

-

Vehicle-mounted solutions

Parts for electric vehicles, commercial vehicles, electric two wheelers, etc -

Industrial Solutions

Cooling scheme for motherboard, controller, battery and other components -

Consumer Products Solutions

Heat dissipation in industries such as purifiers, printers, projectors, etc -

Energy Solutions

Outdoor energy storage power sources, charging stations, photovoltaics, etc

Home

Home