Exhaust efficiency of external air outlet of cooling fan - fan usage status and aging degree

Feng Zhi Yuan

Feng Zhi Yuan

Oct 24,2025

Oct 24,2025

After long-term use, component wear and pollution of fans can lead to a decrease in performance, indirectly weakening the exhaust effect:

1. Ash accumulation and pollution

Dust accumulation on fan blades: Dust adhering to the surface of fan blades can alter their aerodynamic shape (such as increasing angle of attack and flattening curvature), resulting in a decrease in airflow efficiency and a reduction of 10% -30% in air volume; Simultaneously accumulating dust will increase the weight of the fan blades, leading to a decrease in rotational speed.

Dust accumulation at the air outlet/duct: Dust accumulates on the air outlet grille, dust screen, or inner wall of the duct, which reduces the airflow channel and increases wind resistance (such as dust accumulation on the dust screen, which can increase wind resistance by more than 50%), resulting in a sudden drop in exhaust air speed.

2. Wear and aging of components

Bearing wear: Fan bearings (oil containing bearings, ball bearings) will wear out after long-term use, causing an increase in the rotational resistance of the fan blades, a decrease in speed (such as a fan with a nominal 4000RPM, which may drop below 3000RPM after wear), and synchronous attenuation of air volume and pressure.

Motor aging: The aging of the insulation layer of the motor coil can lead to a decrease in motor efficiency (a decrease in the proportion of electrical energy converted into kinetic energy). Even if the power supply is normal, the rotational power of the fan blades will weaken, and the exhaust effect will decrease.

3. Control strategy and speed regulation logic

The control strategy of intelligent speed regulating fans (such as PWM speed regulation) will affect the exhaust effect:

If the speed control logic is conservative (such as starting at full speed only when the temperature reaches 80 ℃), and the fan speed is insufficient in the medium low temperature range (such as 60-70 ℃), the exhaust capacity cannot match the heat dissipation requirements;

If the speed response is delayed (such as when the temperature suddenly rises and the fan takes more than 5 seconds to speed up), it will cause heat accumulation in a short period of time and delay the exhaust effect.

Summary: The core idea for improving exhaust effectiveness

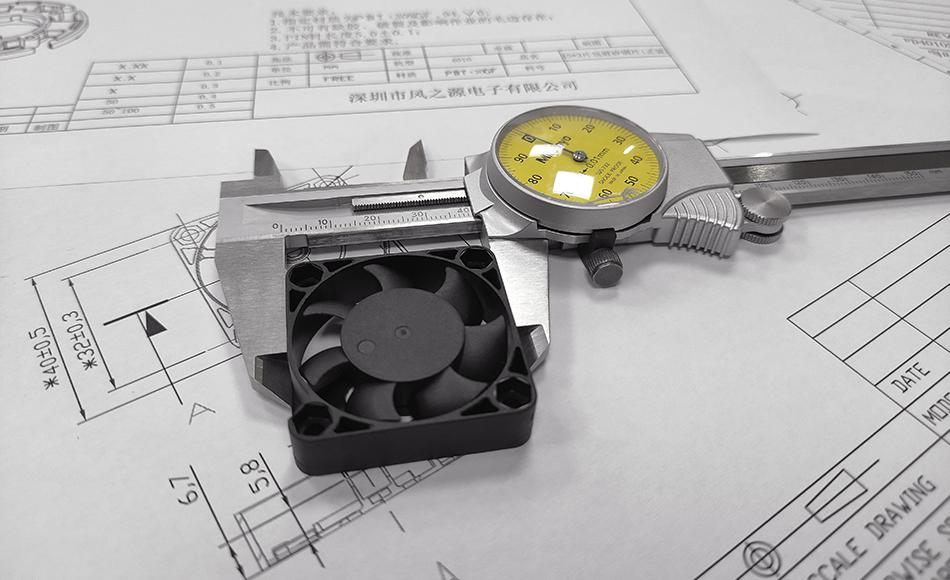

Choose the right fan: Based on the air duct resistance (high resistance, high static pressure fan; low resistance, high air volume fan), prioritize selecting models with high-efficiency brushless motors and streamlined fan blades;

Optimize the air duct: shorten the length of the air duct, reduce the number of bends (≤ 1 90 ° bend), maintain consistent cross-sectional area, and do a good job of sealing (to avoid air leakage);

Simplify the air outlet: reduce the density of the grille, use detachable dust nets (regularly cleaned), and avoid the air outlet being close to obstructions;

Correct installation: Ensure that the fan direction is correct, the installation is firm without gaps, and sufficient diffusion space is reserved at the air outlet;

Regular maintenance: Clean the fan blades, air vents, and air ducts for dust accumulation every 3-6 months, and replace aging fans in a timely manner.

Home

Home

The key factor affecting the lifespan and image quality of projectors - the core role and requirements of cooling fans

The key factor affecting the lifespan and image quality of projectors - the core role and requirements of cooling fans