Exhaust effect of external air outlet of cooling fan - environmental conditions

Feng Zhi Yuan

Feng Zhi Yuan

Oct 14,2025

Oct 14,2025

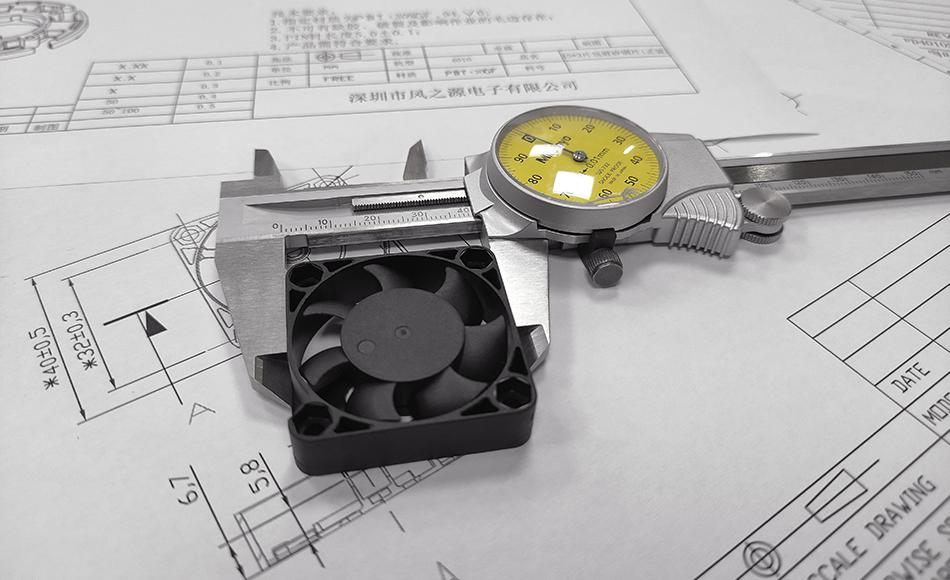

The design characteristics of the air outlet itself determine the "exhaust efficiency" of the airflow

The external air outlet is the "final outlet" of the airflow, and its design directly affects whether the airflow can smoothly leave the system. Key factors include:

1. Sectional area and shape of the air outlet

Sectional area size: The cross-sectional area of the air outlet should match the "cross-sectional area at the end of the air duct" - if the air outlet is too small (such as 50mm at the end of the air duct → 30mm at the air outlet), it will form a "bottleneck", increase wind resistance, accumulate airflow in front of the air outlet, and reduce exhaust speed; If it is too large, the airflow will spread severely, the exhaust heat flux per unit area (heat/area) will decrease, and the heat dissipation effect will be compromised.

Shape of air outlet: The circular air outlet has a more uniform airflow distribution (with minimal wind resistance) and is suitable for high wind speed exhaust; If the corners of the square/strip air outlet are right angles, it is easy to generate eddy currents (with high resistance), and "rounded corner treatment" is needed to reduce losses. For example, the circular air outlet of a car cooling fan has a 10% -15% lower exhaust resistance than the rectangular air outlet of a projector.

2. Air outlet resistance element

The common "protective/filtering elements" in air outlets, such as grilles, dust nets, and guardrails, can increase air resistance and directly weaken the exhaust effect

Grille structure: Dense grilles (such as hole spacing ≤ 2mm) will form "porous resistance", and airflow will be throttled when passing through small holes; If the "rib direction" of the grille is perpendicular to the airflow direction (such as transverse ribs intercepting longitudinal airflow), the resistance will be more than 50% higher than in the parallel direction.

Dust proof mesh density: Although fine dust proof mesh (such as 100 mesh or more) can block small dust, it has great wind resistance - if not cleaned for a long time, dust accumulation will further block the mesh holes, leading to a sudden drop in exhaust efficiency (such as a laptop air outlet dust proof mesh blockage, exhaust efficiency can decrease by 60%, causing overheating and shutdown).

Optimization direction: The resistance element needs to be balanced between protection and wind resistance, such as using a "diagonal grille", "large hole spacing+thick wire dust net", or designing a "detachable cleaning" structure to reduce the impact of dust accumulation.

3. Air outlet guide structure

If there is "airflow interference" around the air outlet (such as being close to walls or obstructions), it is necessary to guide the airflow through a guiding structure:

Air guide plate/cover: Install an arc-shaped air guide plate on the outside of the air outlet to avoid direct impact of airflow on obstructions (such as the computer case air outlet close to the desktop) and generate vortices, allowing the airflow to be smoothly discharged in the direction of the air guide.

Expansion angle of air outlet: The outer side of the air outlet is designed with a "gradually expanding guide cover" (such as gradually expanding from a diameter of 30mm to 50mm), which can reduce the diffusion loss after the airflow is discharged and improve the "effective exhaust range" in the distance (such as the guide cover of the projector air outlet, ensuring that the hot air stays away from the user).

Home

Home

Exhaust efficiency of external air outlet of cooling fan - system adaptability

Exhaust efficiency of external air outlet of cooling fan - system adaptability