Cost structure of cooling fans: from

Feng Zhi Yuan

Feng Zhi Yuan

Jul 04,2025

Jul 04,2025

The cost of a cooling fan is not only the purchase price, but also includes the full lifecycle costs such as transportation, installation, maintenance, and disposal. The product manager needs to optimize the cost structure through "value engineering":

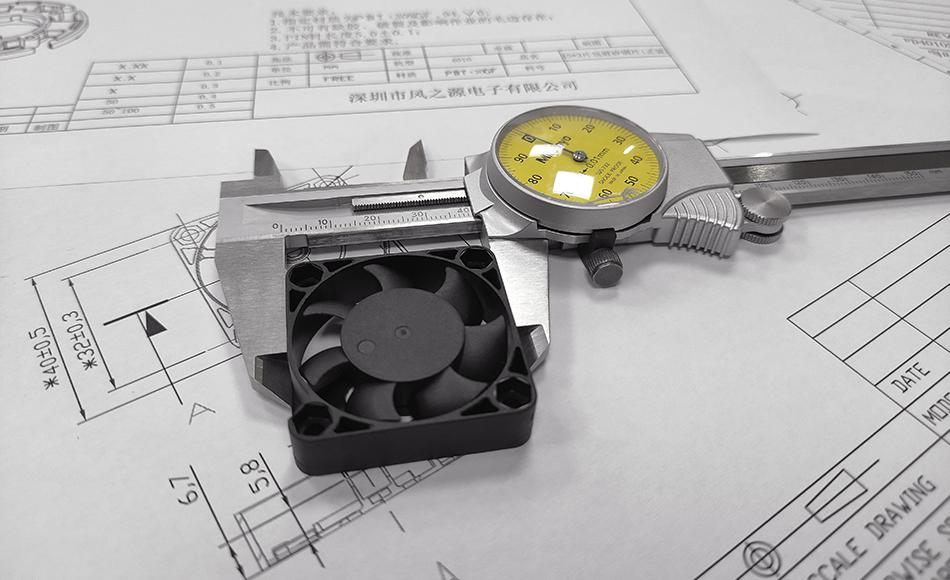

Material selection: A certain PC fan manufacturer changed the "aluminum alloy frame" to "nylon+glass fiber composite material", reducing the cost of a single unit by 30 yuan. However, due to a 20% reduction in weight, transportation costs were reduced by 5 yuan per unit, resulting in a total cost reduction of 35 yuan.

Manufacturing process: A certain automotive fan manufacturer has adopted "injection molding+ultrasonic welding" instead of "metal stamping+screw assembly", reducing the production time of a single unit from 120 seconds to 45 seconds, reducing labor costs by 60%, and increasing the yield rate from 95% to 99%.

Certification cost: A certain export-oriented fan manufacturer has achieved CE (EU), UL (North America), and CCC (China) certification through "modular design", reducing the certification cost from 1.2 million yuan to 400000 yuan. However, a "detachable grounding terminal" needs to be reserved in the design, increasing the cost per unit.

Home

Home

Prospects of the radiator industry

Prospects of the radiator industry